Let’s conclude our journey to discover the quality tests performed by the Sanmiro R&D team with the fatigue test, which is included in the set of analyses required by the EN 12983-1 standard.

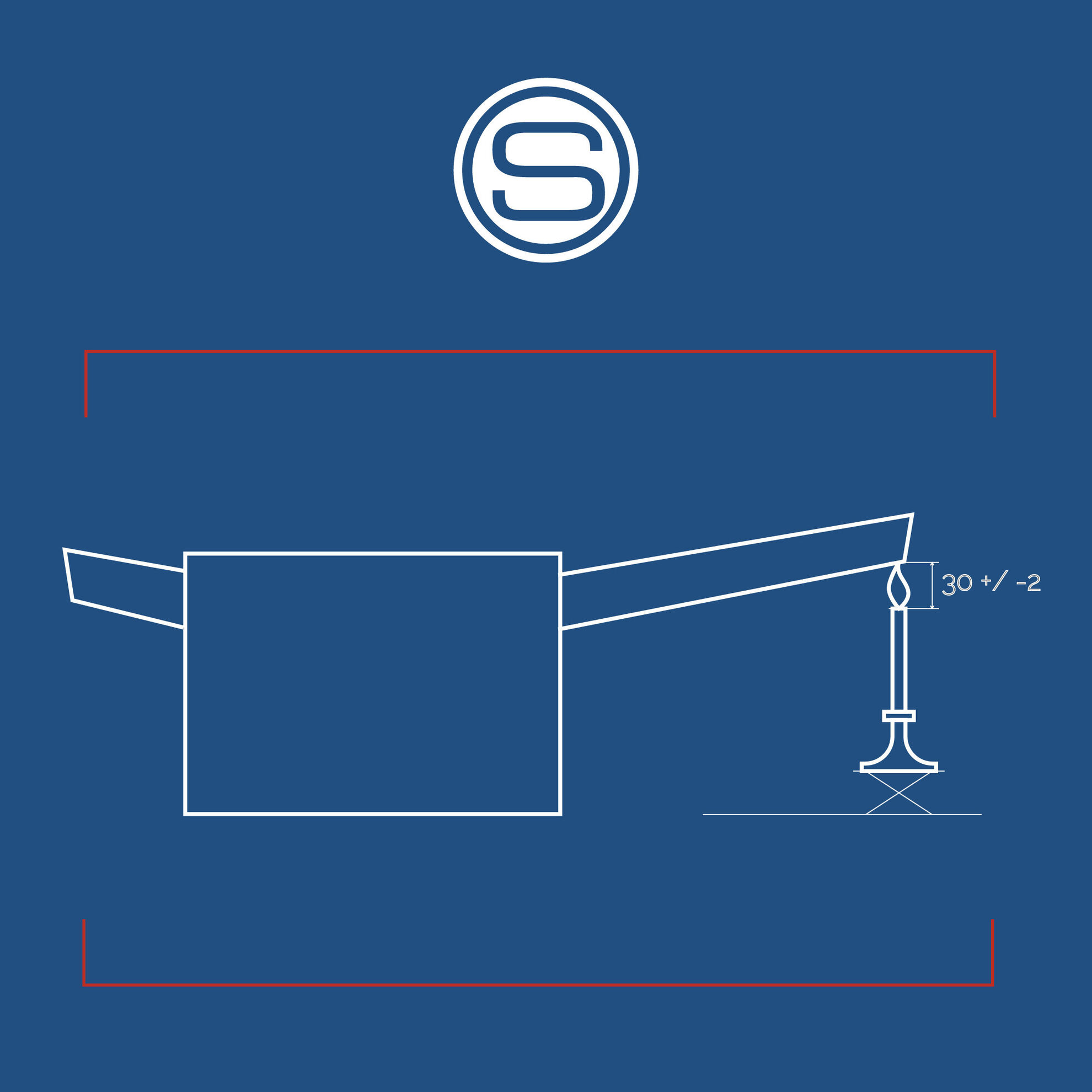

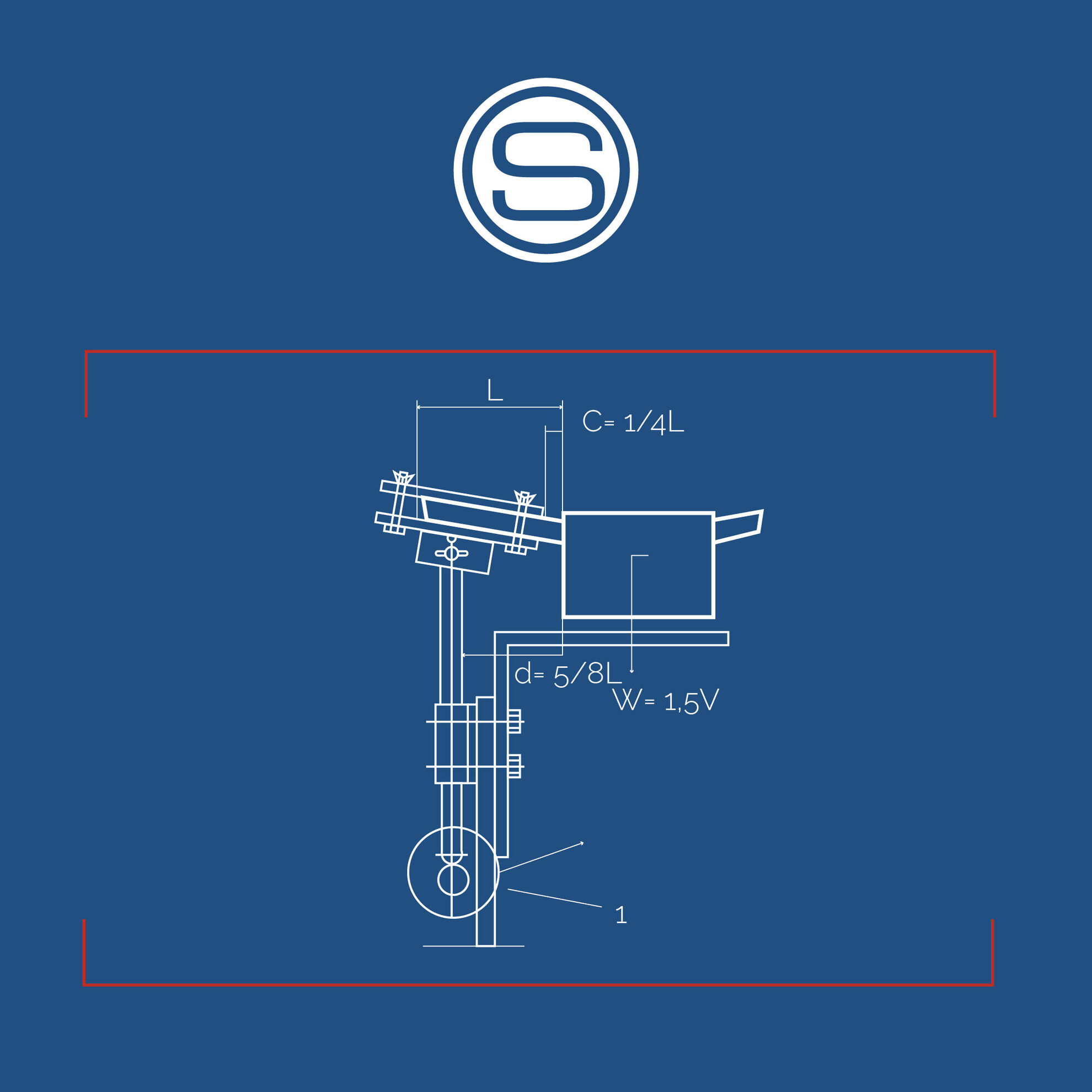

The objective of the fatigue test is to verify the behaviour of an item (in this case, handles, knobs and side handles for pots and pans) under stress, simulating normal daily use.

Specifically, the test consists of subjecting the products, filled with a mass equal to 1.5 times their volume, to a test of 15,000 lifting cycles.

At the end of the test, the tool must not show any breakage, wear or other damage, otherwise it will not pass the test.

These tests are conducted in the Sanmiro R&D laboratory, the feather in the company’s cap, which is able to test, experiment, correct and optimise samples and production quickly and accurately.

This is a priceless and fundamental department for the greater guarantee and protection of the customer as well as the end consumer.

For Sanmiro, quality and safety standards have always been, and remain, essential values.

Let's review the most important tests Sanmiro products undergo before being launched on the market.

Heat resistance test

This test consists of testing products placed inside a self-ventilated Binder oven, preheated to 150°, to assess the quality of the raw material we are using and to ensure that we are producing in accordance with European industry regulations.

Flexural strength test

This is a very demanding test for cookware accessories. A force of 100 N (10.2 kg) is applied to the end of the item for 30 seconds, with the product being tested firmly attached to the worktop. The test is passed if no cracks or breaks occur.

Torsion strength test

During this test, the handle is clamped on an inclined plane so that it is horizontal, and fixed on a clamp equipped with a digital torque meter and a clinometer capable of measuring the twist reached during the test. A torque of 5 Nm is applied to it to the right and then to the left, in order to check any breakage and the level of twisting caused during the test.

Quality always comes first for Sanmiro

These analyses, conducted in the company's in-house laboratory, allow us to monitor the complete life cycle of Sanmiro products, from their conception and graphic design through prototyping and testing to actual production.

A process we are very proud of that guarantees efficiency and speed at all stages of development, as well as total control over the product, with the aim of producing cookware accessories of the highest quality and safety for our customers.

If you want to develop a new line of safe, high-quality kitchen products, here are our references:

visit sanmiro.com

contact us This email address is being protected from spambots. You need JavaScript enabled to view it.